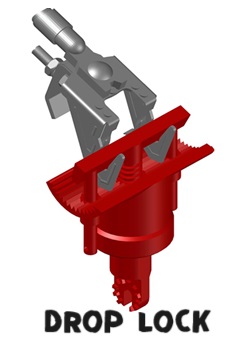

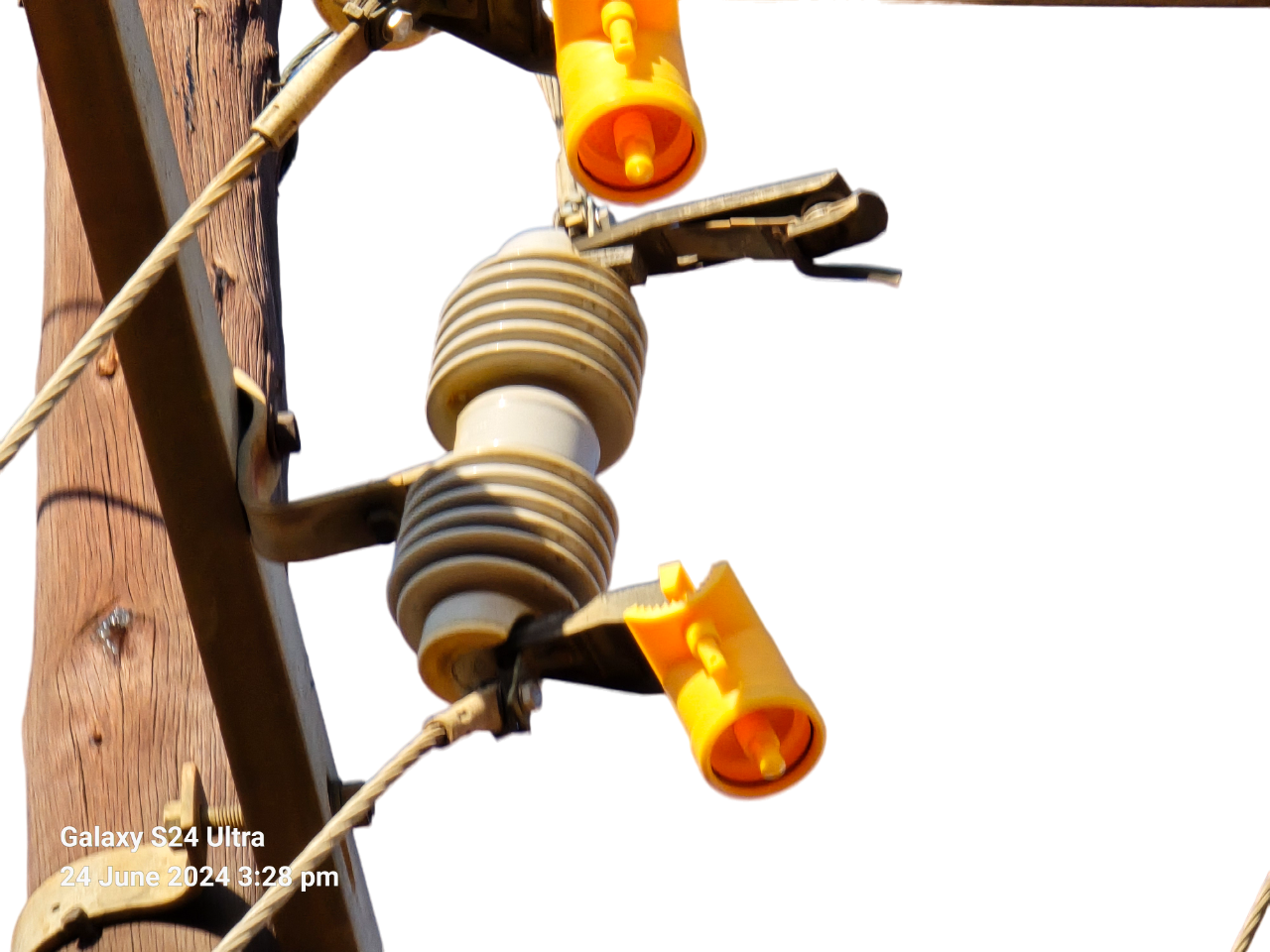

Drop Lock Lockout System

Drop Lock Lockout System

BERMOR ELECTRONICS saw a big need for a lockout device that will make it possible for end users such as mines and farmers and especially ESKOM to lock out transformers, power lines and certain infrastructure in the field.

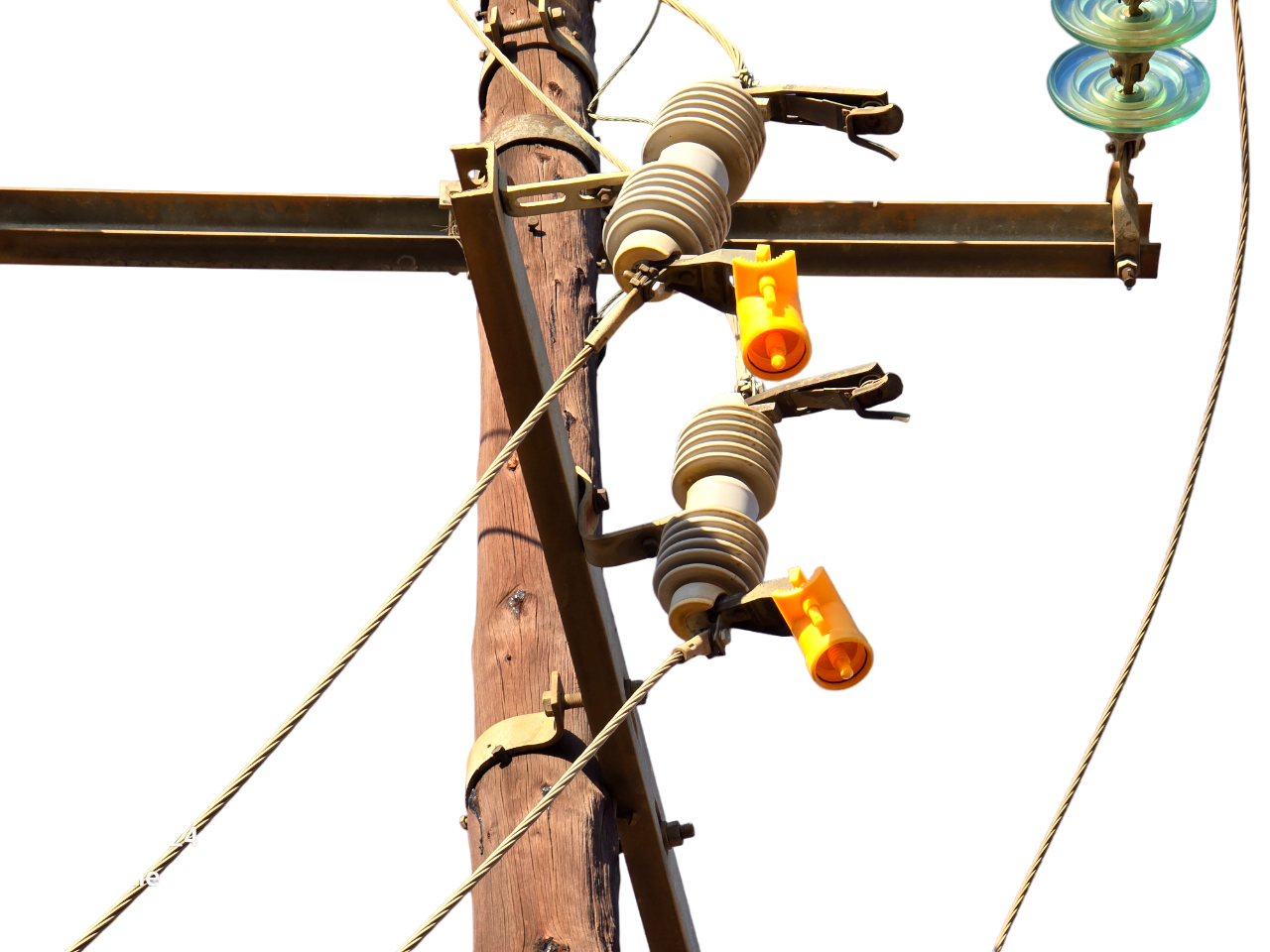

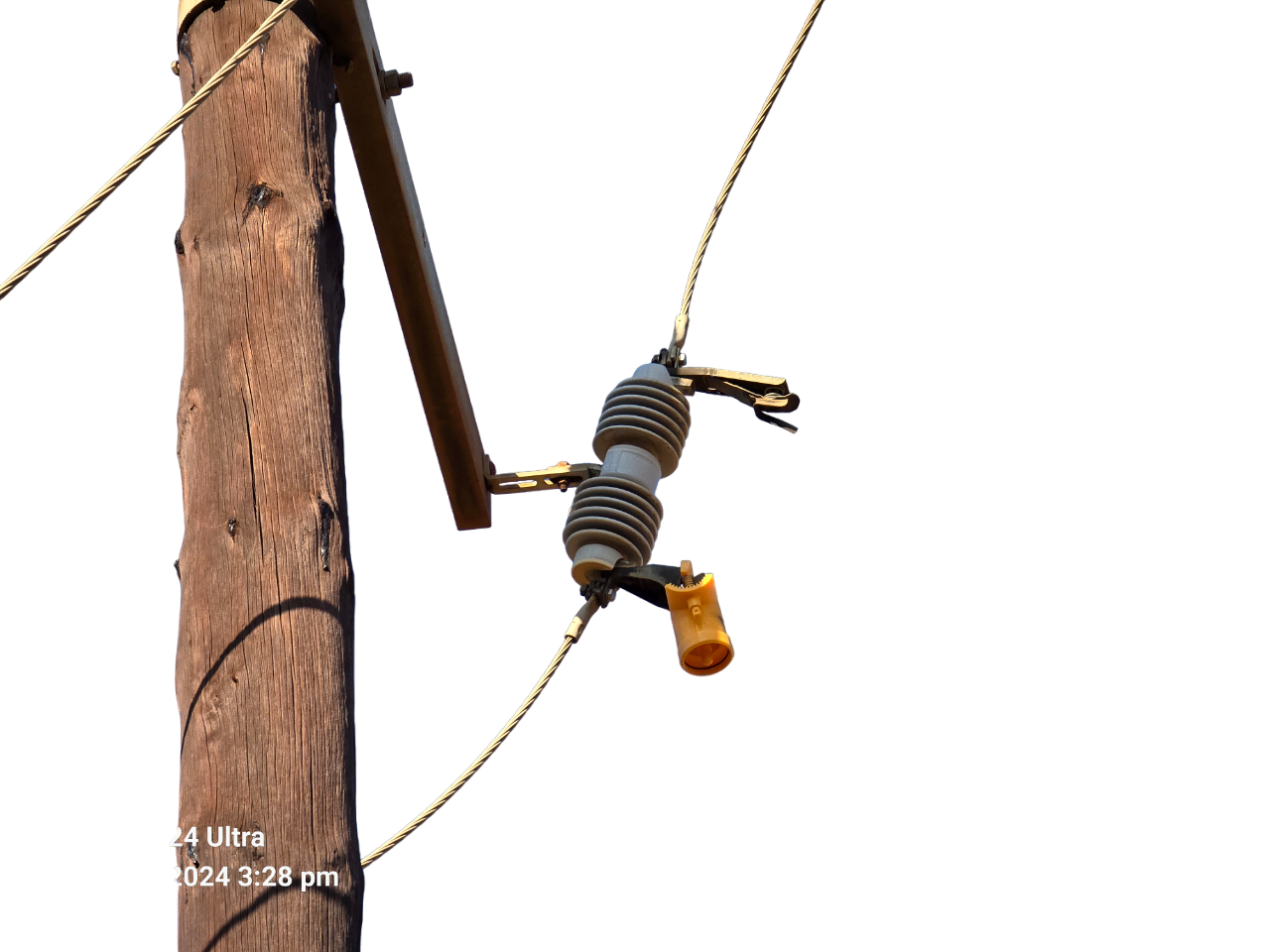

BERMOR ELECTRONICS came up with the idea to build a lock out device that you can install with an industry standard hot stick on to a dropout base/dropout fuse holder.

Our device is a first of its kind on the market.

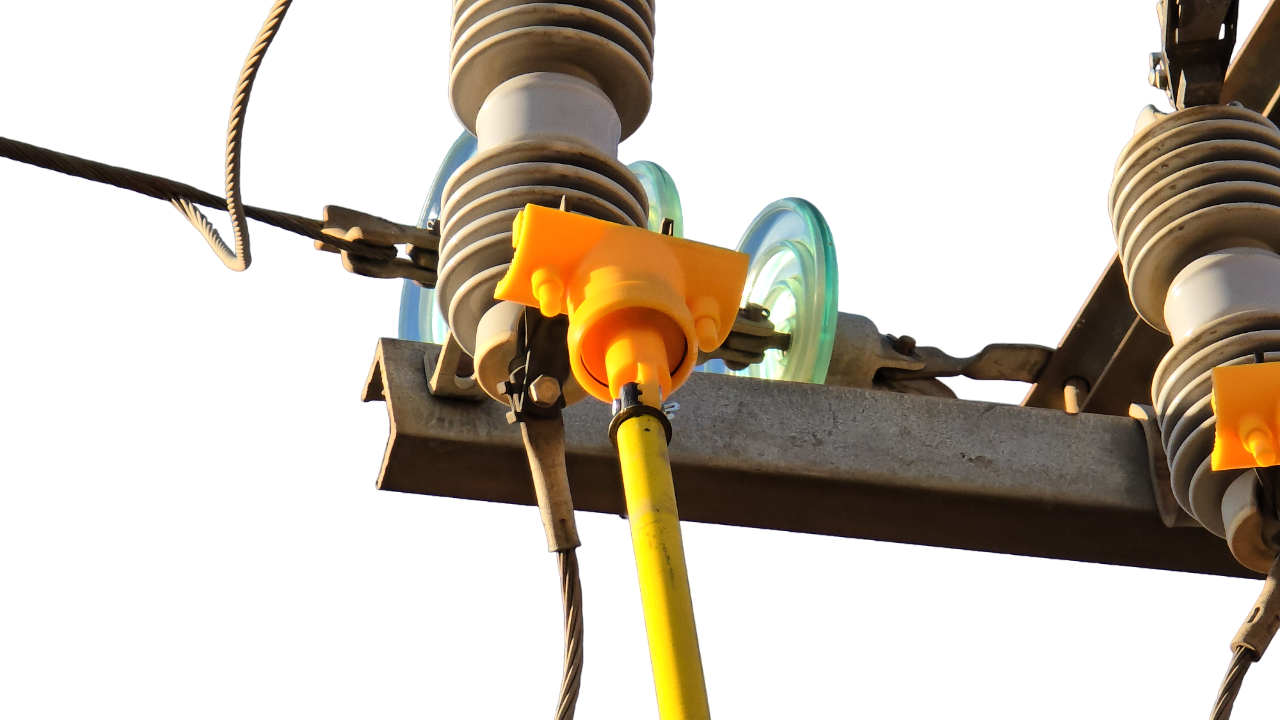

ESKOM is sitting with a big need for a lockout device for dropout bases. A dropout base is installed before most mv transformer installation in the industry. Eskom uses the dropout base as a means to isolate or remove power if the end user does not pay their bill. But a hot stick can be used to replace the dropout fuse section, that is readily available over the counter at most electrical suppliers. Our device will allow the client to lock the bottom section of the dropout fuse holder that will prevent end users to switch back on the power themselves.

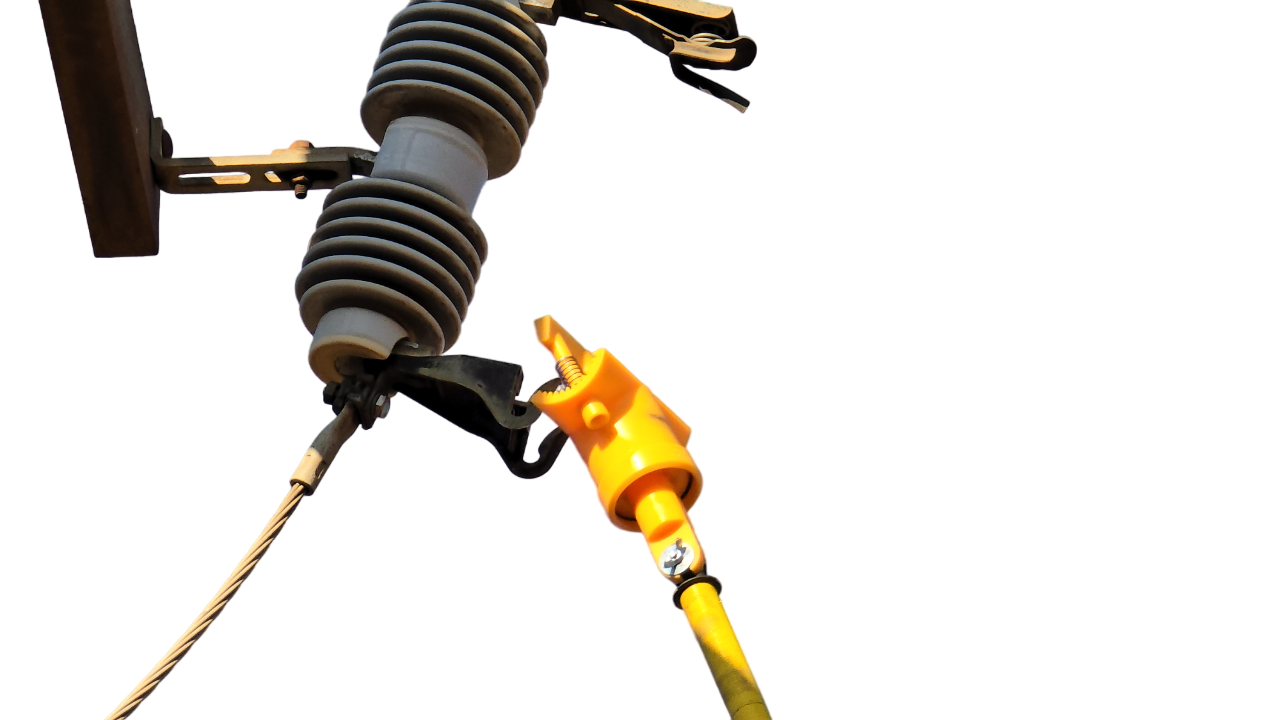

The Mining and agriculture application is just as lucrative. All the Mines are in dire need of a device that will allow the electricians to lock out a transmission line, ring feed or transformer to be able to safely work on the apparatus. It is a requirement in the OHSA Act, DMRE and in all mine COP’S that a physical means of disconnection must be made and that all attempts must be made by the Employer to avoid inadvertent switching that can endanger the live of any person.

We have spent almost two years in development and testing to get our product to be as efficient and as cost effective as possible.

We concentionalized, designed and manufactured the Lockout device in house.

The device is made of high-quality ABS Plastic that is high in tensile strength, drop resistant and uv resistant.

Operating Procedure

Installation:

- Remove lockout fuse base with hot stick/link stick

- Install Lockout cup/key on to your industry standard Hot Stick/Link Stick

- Place DROP LOCK on top of the key and make sure that the special key fits and mesh

- Lift hot stick up to the dropout and drop the DROP LOCK into place

- Turn the hot stick/link stick clock wise to tighten the DROP LOCK in to place

- Pull down on the hot stick/ link stick to remove key/cup f rom the DROP LOCK

- The dropout is now locked out

- Remote key from the hot stick and place in lockout box

Removal:

- Install DROP LOCK Key on to hot stick

- Extend link stick to the base of the DROP LOCK

- Push the cup/key into the flared bottom opening of the unit

- Push the cup/key past the O-ring

- Turn the hot stick until the unique keys drop into the indent

- Turn the hot stick/link stick counter clockwise to loosen the DROP LOCK

- Lift hot stick to remove DROP LOCK device

Conclusion

The drop lock system was designed with the following purpose:

- To eliminate the need of a gang-link isolator system

- To save cost due the high price and installation cost of gang-link

- To avoid the ability to break the lock and inadvertantly energizing the transformer or circuit after the isolator, thus causing harm to human & equipment

- Avoiding the breaking of locks to open the isolator for the purpose of theft

- Avoid inadvertant power energize after a non-payment cut off

- To be used a means of a physical lockout for mv transmission lines

ABS Material Data Sheet